Electromagnetic Flow Meter

General Description

Electromagnetic flowmeter suits for all kinds of liquids’ flow measuring such as electronic conductivity liquid, mud and slurry etc. on the basis of its min. conductivity. The result cannot be affected by temperature, pressure, viscosity and density.

It can also be used for measuring corrosive material as long as the right material has been chosen for the lining material. Solid medium will not affect the result.

Flow sensor and intelligent converter compact or separately composes a complete flowmeter.

Application

The main application area;

Pure water, sewage water, sea water

Electronic manufacture and assign

Chemistry and industrial medicine

Food industry

Feature

No move assembly, no abrasion

Measuring range rate: 1:100

No flow enhance equipment

Suits for various of electronic conductivity liquid

No affect from temperature, viscosity, pressure and density

Anti-corrosion

Measure both to and reverse flow

Huge display, easy operate

Long-term EEPROM to save data when lose power

Support MODBUS/HARTcommunication protocal

Wide working volts range

Self diagnose

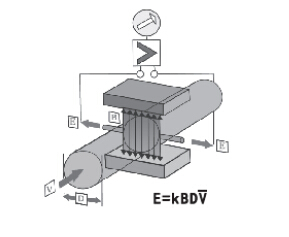

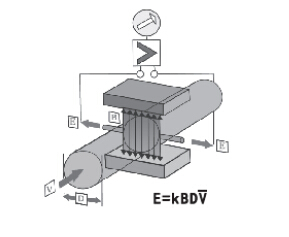

Working principle

Its measuring principle bases on Faraday electromagnetic induction law:

When the liquid flow through the measuring pipe which all around magnetic field, the two vertical direction will have the induced electromotive force which is proportional with the mean velocity of stream.

Flowmeter consists of sensor and converter. Converter transfer field current to inner loop of the sensor to engender magnetic field. Conductivity liquid flow through the measuring pipe and get induced force because of cutting magnetic line. By then the electrode around the pipe wall incept induced force and transfer them to converter through signal wire. Converter filer induced force, spread, calculate and exchange them into proportional standard current signal and frequency signal.

Technical spec

Display reaches 8element liquid crystal display, current clock to indicate flow data. two kinds of units to choose: m3 or L.

Structure inserted style, compact type or separate type

Measuring medium liquid or solid-liquid two phase fluid, conductivity >0.5μs/cm2

Range 0.05m/s~12m/s

Accuracy range between 0.1m/s~10m/s can be 0.5%

DN(mm) 6mm~2000 mm

PN PN6, PN10,PN16,PN25,PN40,PN63,PN100,PN160,PN250,PN420 optional

Output signal 4~20mA or frequency

Communication RS485,support MODBUS protocol (not standard)、 support HART(option)

Connection DN6~DN2000 flange connection

Connection standard suits for all kinds of flange standard (eg:BS EN1092-1)

Standard accuracy apply to EN1434-1:2003 standard

CE certificate apply to LVD 2006/95/EC and EMC 2004/108/EC

EN 61326-1:2006 radiation standard (express apply to BS EN50081-1)

EN 61326-1:2006 anti-jamming standard (express apply to BS EN50082-1)

EN 61010-1:2001

Protection grade compact type for IP65,separately type for IP67or IP68(optional)

Power supply AC86~220V or DC24V(optional)

Ambient temperature 5~55℃

Ambient huminity <85 % r.h (noncondensation)

|

DN(mm)

|

Lining material

|

Flow range ( m3/h )

|

Size( mm )

|

Connection size ( mm )

|

|

Ne

|

FEP

|

PTFE

|

Normal

|

Min.

|

Max

|

L

|

H

|

B

|

b

|

¢K

|

n-¢d

|

¢D

|

|

10

|

|

●

|

|

0.7

|

0.03

|

2.8

|

160

|

254

|

152

|

102

|

65

|

4-¢14

|

95

|

|

15

|

|

●

|

|

1.5

|

0.06

|

6.4

|

160

|

254

|

65

|

4-¢14

|

95

|

|

20

|

|

●

|

●

|

2.5

|

0.11

|

11

|

160

|

254

|

75

|

4-¢14

|

105

|

|

25

|

|

●

|

●

|

3.5

|

0.18

|

18

|

160

|

254

|

85

|

4-¢14

|

115

|

|

32

|

|

●

|

●

|

6

|

0.29

|

29

|

270

|

100

|

4-¢18

|

140

|

|

40

|

|

●

|

●

|

10

|

0.45

|

45

|

200

|

280

|

110

|

4-¢18

|

150

|

|

50

|

●

|

●

|

●

|

15

|

0.71

|

71

|

294

|

125

|

4-¢18

|

165

|

|

65

|

●

|

●

|

●

|

25

|

1.19

|

119

|

313

|

145

|

8-¢18

|

185

|

|

80

|

●

|

●

|

●

|

40

|

1.81

|

181

|

326

|

160

|

8-¢18

|

200

|

|

100

|

●

|

●

|

●

|

60

|

2.83

|

283

|

250

|

344

|

180

|

8-¢18

|

220

|

|

125

|

●

|

●

|

●

|

100

|

4.42

|

442

|

372

|

210

|

8-¢18

|

245

|

|

150

|

●

|

●

|

●

|

150

|

6.36

|

636

|

300

|

403

|

240

|

8-¢22

|

285

|

|

200

|

●

|

●

|

●

|

250

|

11.3

|

1130

|

350

|

460

|

295

|

12-¢22

|

340

|

|

250

|

●

|

●

|

●

|

400

|

17.66

|

1766

|

400

|

511

|

350

|

12-¢22

|

390

|

|

300

|

●

|

●

|

●

|

600

|

25.43

|

2543

|

500

|

565

|

400

|

12-¢22

|

440

|

|

350

|

●

|

●

|

●

|

750

|

34.62

|

3462

|

620

|

460

|

16-¢22

|

500

|

|

400

|

●

|

●

|

●

|

900

|

45.22

|

4522

|

600

|

675

|

55

|

16-¢22

|

565

|

|

450

|

●

|

|

●

|

1200

|

57.23

|

5723

|

|

727

|

|

|

565

|

20-¢26

|

615

|

|

500

|

●

|

|

●

|

1500

|

70.65

|

7065

|

782

|

620

|

20-¢26

|

670

|

|

600

|

●

|

|

●

|

2500

|

101.74

|

10174

|

782

|

725

|

20-¢30

|

780

|

|

700

|

●

|

|

●

|

4000

|

138.47

|

13847

|

700

|

1068

|

840

|

24-¢30

|

895

|

|

800

|

●

|

|

●

|

5000

|

180.86

|

18086

|

800

|

1157

|

950

|

24-¢34

|

1010

|

|

900

|

●

|

|

●

|

6000

|

228.91

|

22891

|

900

|

1230

|

1050

|

28-¢34

|

1110

|

|

1000

|

●

|

|

●

|

8000

|

282.60

|

28260

|

1000

|

1332

|

1160

|

CoryRight © China Smart Sensor Co. All Rights Reserved.

|